The Ultimate Guide to Polymer Banknotes: The Tech, The Security, and The Future of Money

The Ultimate Guide to Polymer Banknotes: The Tech, The Security, and The Future of Money

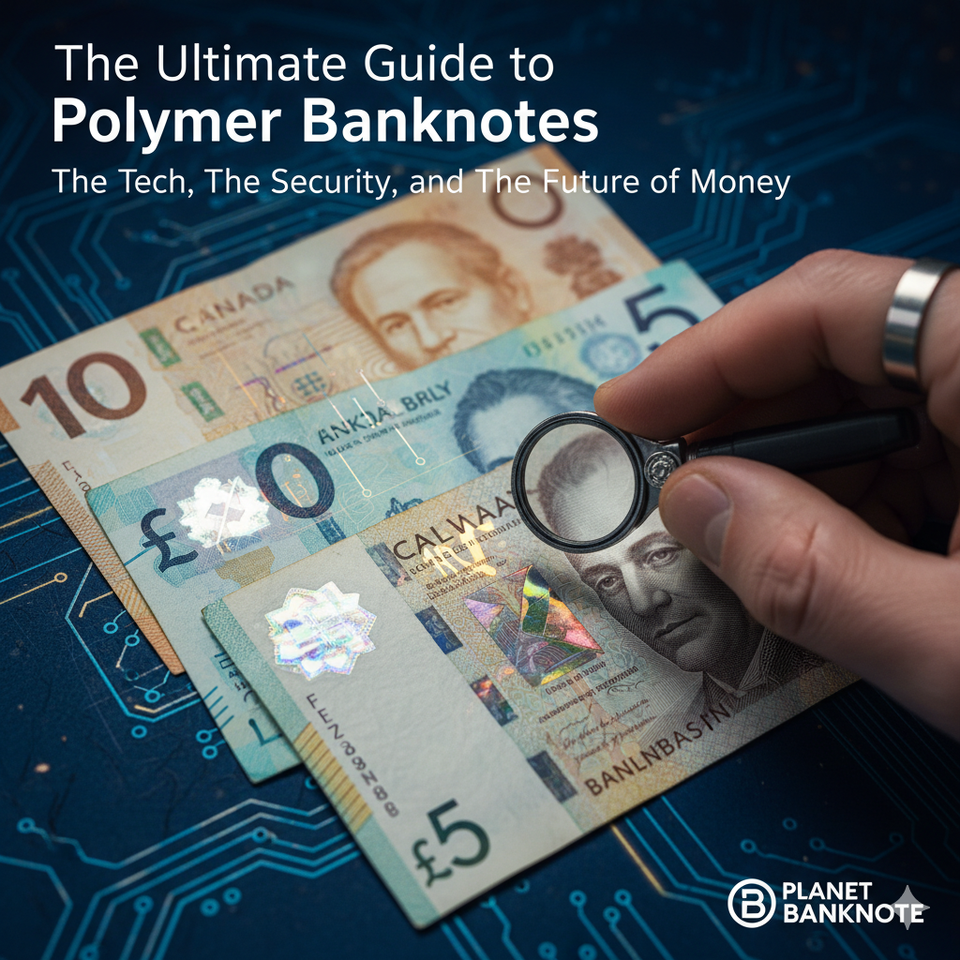

For centuries, money was paper. Now, it's plastic. That flimsy-feeling, futuristic banknote in your wallet is one of the most advanced pieces of technology you own. This transformation from fibrous cotton to slick polymer is not a gimmick; it is a calculated, high-tech upgrade on a global scale, fundamentally redefining what currency can and should be.

The revolution began as a response to a crisis. By the 1960s and 1970s, the increasing availability of high-resolution color photocopiers and printers posed an existential threat to global currencies.

Their solution, which took two decades and over $20 million in research

This release was, in fact, one of the most successful public beta tests in technological history. The RBA had spent a fortune developing the technology and a full, immediate switch was deemed too risky.

The world took notice. This Australian innovation quickly became the new global standard for security. Key adopters followed, including New Zealand (1999)

This guide will deconstruct why this shift is happening, how this high-tech "plastic" is engineered, what makes it a miniature fortress, and what it means for the future of money and collecting.

The "Why" - The Systemic Failures of Paper Currency

Before polymer became the solution, paper was the undeniable problem. It is a common misconception that "paper" money is made from wood pulp. For durability, it is actually a robust substrate made from a blend of cotton and linen fibers.

Weakness 1: Physical Durability (The "Wash Test")

The most obvious failing of cotton-paper currency is its physical fragility. The substrate is porous and fibrous

-

Durability: It wears out, tears, and over time, becomes "limp," losing all crispness.

18 -

Water: It is, of course, non-waterproof.

17 -

Lifespan: The operational lifespan of paper currency is dismally short. Before switching, the RBA found its paper notes lasted only six to twelve months in circulation.

20 21

Weakness 2: Hygiene (The "Biohazard" in Your Wallet)

The porous nature of cotton-paper makes it an ideal vehicle for contaminants.

Scientific studies have confirmed this risk for decades. Paper currency is a known fomite (an object capable of carrying infectious organisms). Researchers have isolated a rogue's gallery of pathogenic microorganisms from circulating banknotes, including E. coli, Salmonella, and methicillin-resistant Staphylococcus aureus (MRSA).

The data on viral transmission is even more striking. Laboratory simulations have shown that the human influenza virus can be transmitted from banknotes to hands.

Weakness 3: Security (The "Casual Counterfeiter")

While durability and hygiene are serious flaws, the primary driver for the invention of polymer was security.

This development exposed the fundamental vulnerability of paper. The security of paper currency is based on features that are two-dimensional or embedded within the substrate.

A high-resolution scanner, however, can easily replicate these features in 2D. A scanner and printer can print a faint, fuzzy image to simulate a watermark.

Paper currency lost the security war when its primary defenses could be effectively simulated on a 2D plane. The only viable solution was to invent a new currency substrate with features that are physically impossible to replicate with ink on paper. This is the central genius of polymer: the substrate itself becomes the security feature. A counterfeiter cannot "print" a transparent window.

The "How" - Deconstructing Polymer Currency

To the average person, it is just "plastic money." To a material scientist, it is a precisely engineered marvel. The material is not just any plastic; it is a specific synthetic polymer called Biaxially Oriented Polypropylene, or BOPP.

The Manufacturing Process: The "Bubble"

The creation of this substrate is a feat of industrial engineering.

-

It begins as small, raw polymer pellets.

34 -

These pellets are melted and extruded through a die.

-

The most advanced method, used by manufacturers like Innovia Films, is the "bubble" process.

35 34 -

As this giant bubble inflates and cools, it is mechanically stretched in two directions at once (lengthwise and widthwise).

13

This biaxial stretching is the technological secret sauce. If the plastic were simply rolled flat ("mono-axially" stretched), it would be strong in one direction but tear easily in the other, like a cheap plastic bag. The dual-direction stretching pulls the polymer chains taut in a cross-hatched pattern. This is what imparts the "distinctive balanced tensile properties".

This process creates a perfectly clear, transparent film. This film is then coated with layers of white and other inks to make it opaque and printable, leaving specific areas clear to create windows.

The Benefits: A Direct Solution to Paper's Flaws

The properties of BOPP film directly solve every one of paper's systemic weaknesses.

1. Extreme Durability

Polymer notes last significantly longer than their paper predecessors. The most conservative estimates, used by the Bank of England, state they last 2.5 times longer.13 However, the Bank of Canada, with years of real-world data, states their polymer notes last four times longer than the paper notes they replaced.40 Their data projects a lifespan of 11 years for a $10 note and 16 years for a $20 note.40 They are fully waterproof, tear-resistant, and can withstand extreme temperatures without damage.21

2. Superior Cleanliness

The surface of a polymer banknote is smooth and non-porous.37 Unlike paper, which acts like a sponge, the polymer substrate prevents dirt, oils, and moisture from penetrating.41 A 2016 study at Harper Adams University found that bacteria found on human hands are less capable of sticking to plastic notes and die off faster than on cotton-based paper.42 They can even be wiped clean with a damp cloth without being damaged.42

3. Long-Term Cost-Effectiveness

This is the business case that convinces central banks. Polymer substrate is significantly more expensive to produce upfront than paper.20 The economic victory is won through longevity.

A landmark 2019 analysis by the Reserve Bank of Australia quantified this benefit.20 It found that, despite the higher printing cost, the switch to polymer resulted in net savings of close to $1 billion (inflation-adjusted) over a 25-year period.20 For high-transaction denominations like the $5 and $10, which previously wore out in months, the initial investment was paid back in just four years.20

4. Surprising Eco-Friendliness

The most common objection to polymer—"but it's plastic"—is also the most misunderstood. Worn-out paper banknotes are notoriously difficult to recycle due to the inks, security threads, and cotton fibers, and are often shredded and landfilled or burned.44

Polymer banknotes, at the end of their long operational lives, are 100% recyclable.

Furthermore, comprehensive Life Cycle Assessments (LCAs) conducted by the Bank of Canada and the Bank of England both concluded that polymer banknotes have a smaller environmental footprint than paper.

Table 1: Paper vs. Polymer: A Technological Showdown

| Feature | Cotton-Paper Substrate | Polymer (BOPP) Substrate |

| Lifespan |

6-18 months [20, 21] |

8-16+ years (approx. 4x longer) |

| Durability |

Porous; absorbs water, dirt. Tears easily |

Non-porous; waterproof, tear-resistant, high tensile strength [36, 37] |

| Hygiene |

Porous; absorbs oils. Harbors bacteria/viruses for days, even weeks [23, 25] |

Non-porous; repels dirt. Bacteria die off faster, can be wiped clean [41, 42] |

| Core Security |

2D/Embedded (e.g., watermark). Vulnerable to high-res scanning [2, 26] |

3D/Substrate (e.g., window). Cannot be replicated by 2D printing |

| End-of-Life |

Difficult to recycle; often landfilled or burnt |

100% recycled into pellets for new plastic goods (e.g., compost bins) |

| Long-Term Cost |

Low print cost, high replacement cost |

High print cost, low replacement cost. (Net $1B savings for Australia) |

The "Mini-Fortress" - A Deep Dive into Polymer Security Features

Polymer is not merely a substrate; it is a security platform. Its true genius lies in its ability to host a suite of advanced security features that are physically impossible to create on paper. These features are layered, creating defenses that work on three levels: Level 1 (for the public), Level 2 (for cash-handlers with tools), and Level 3 (covert features for central banks).

Feature 1: The Transparent Window

This is the most obvious, elegant, and effective Level 1 feature.

The manufacturing process starts with a 100% transparent BOPP film.

This single feature instantly defeats all casual counterfeiters.

Feature 2: Optically Variable Devices (OVDs) - The Art of Nanotechnology

The transparent window also serves as a high-tech "frame" for even more complex features. Optically Variable Devices (OVDs) are complex images that change their appearance (such as their color or the image itself) when the note is tilted.

A prime example is the UK's £20 note. Its large window features a complex blue and gold metallic foil depicting the Margate lighthouse.

However, "hologram" is a generic term that hides a crucial, expert-level distinction. Most "holograms" seen on consumer products are a publicly known, pixel-based technology.

High-security OVDs, such as the KINEGRAM® (used on the Austrian 500 shilling)

Feature 3: Metameric Inks (The Chameleon Effect)

This is a brilliant Level 2 security feature based on the physics of light. Metameric security involves not one, but a pair of specialized inks.

These two inks are spectrally matched so that, under one light source (like the normal white light in a room), they appear to be the exact same color.

A counterfeiter's inkjet printer, mixing CMYK inks, can only create one color. It cannot replicate the hidden metameric property of two different inks masquerading as one. A bank teller or cashier can use a simple filter to check a suspicious note. If a hidden numeral or pattern does not appear, the note is instantly flagged as a fake.

Feature 4: Intaglio (Raised) Printing - A Sharper Feel

Intaglio is a classic, high-security printing method where thick, heavy ink is applied to the plate with immense pressure, forcing it onto the substrate to create a distinctive, tactile "raised" print that can be felt with a finger.

On porous cotton-paper, the intaglio ink is pressed into the fibers.

On the smooth, non-porous polymer substrate

Feature 5: Microprinting and Covert Features

Beyond these flagship features, the polymer substrate is layered with other defenses. This includes microprint, which appears to be a simple line to the naked eye but is revealed under magnification to be tiny, perfectly legible text (e.g., "£20" or "Bank of England").

The "Why" - The Systemic Failures of Paper Currency

Before polymer became the solution, paper was the undeniable problem. It is a common misconception that "paper" money is made from wood pulp. For durability, it is actually a robust substrate made from a blend of cotton and linen fibers.

Weakness 1: Physical Durability (The "Wash Test")

The most obvious failing of cotton-paper currency is its physical fragility. The substrate is porous and fibrous

-

Durability: It wears out, tears, and over time, becomes "limp," losing all crispness.

18 -

Water: It is, of course, non-waterproof.

17 -

Lifespan: The operational lifespan of paper currency is dismally short. Before switching, the RBA found its paper notes lasted only six to twelve months in circulation.

20 21

Weakness 2: Hygiene (The "Biohazard" in Your Wallet)

The porous nature of cotton-paper makes it an ideal vehicle for contaminants.

Scientific studies have confirmed this risk for decades. Paper currency is a known fomite (an object capable of carrying infectious organisms). Researchers have isolated a rogue's gallery of pathogenic microorganisms from circulating banknotes, including E. coli, Salmonella, and methicillin-resistant Staphylococcus aureus (MRSA).

The data on viral transmission is even more striking. Laboratory simulations have shown that the human influenza virus can be transmitted from banknotes to hands.

Weakness 3: Security (The "Casual Counterfeiter")

While durability and hygiene are serious flaws, the primary driver for the invention of polymer was security.

This development exposed the fundamental vulnerability of paper. The security of paper currency is based on features that are two-dimensional or embedded within the substrate.

A high-resolution scanner, however, can easily replicate these features in 2D. A scanner and printer can print a faint, fuzzy image to simulate a watermark.

Paper currency lost the security war when its primary defenses could be effectively simulated on a 2D plane. The only viable solution was to invent a new currency substrate with features that are physically impossible to replicate with ink on paper. This is the central genius of polymer: the substrate itself becomes the security feature. A counterfeiter cannot "print" a transparent window.

The "How" - Deconstructing Polymer Currency

To the average person, it is just "plastic money." To a material scientist, it is a precisely engineered marvel. The material is not just any plastic; it is a specific synthetic polymer called Biaxially Oriented Polypropylene, or BOPP.

The Manufacturing Process: The "Bubble"

The creation of this substrate is a feat of industrial engineering.

-

It begins as small, raw polymer pellets.

34 -

These pellets are melted and extruded through a die.

-

The most advanced method, used by manufacturers like Innovia Films, is the "bubble" process.

35 34 -

As this giant bubble inflates and cools, it is mechanically stretched in two directions at once (lengthwise and widthwise).

13

This biaxial stretching is the technological secret sauce. If the plastic were simply rolled flat ("mono-axially" stretched), it would be strong in one direction but tear easily in the other, like a cheap plastic bag. The dual-direction stretching pulls the polymer chains taut in a cross-hatched pattern. This is what imparts the "distinctive balanced tensile properties".

This process creates a perfectly clear, transparent film. This film is then coated with layers of white and other inks to make it opaque and printable, leaving specific areas clear to create windows.

The Benefits: A Direct Solution to Paper's Flaws

The properties of BOPP film directly solve every one of paper's systemic weaknesses.

1. Extreme Durability

Polymer notes last significantly longer than their paper predecessors. The most conservative estimates, used by the Bank of England, state they last 2.5 times longer.13 However, the Bank of Canada, with years of real-world data, states their polymer notes last four times longer than the paper notes they replaced.40 Their data projects a lifespan of 11 years for a $10 note and 16 years for a $20 note.40 They are fully waterproof, tear-resistant, and can withstand extreme temperatures without damage.21

2. Superior Cleanliness

The surface of a polymer banknote is smooth and non-porous.37 Unlike paper, which acts like a sponge, the polymer substrate prevents dirt, oils, and moisture from penetrating.41 A 2016 study at Harper Adams University found that bacteria found on human hands are less capable of sticking to plastic notes and die off faster than on cotton-based paper.42 They can even be wiped clean with a damp cloth without being damaged.42

3. Long-Term Cost-Effectiveness

This is the business case that convinces central banks. Polymer substrate is significantly more expensive to produce upfront than paper.20 The economic victory is won through longevity.

A landmark 2019 analysis by the Reserve Bank of Australia quantified this benefit.20 It found that, despite the higher printing cost, the switch to polymer resulted in net savings of close to $1 billion (inflation-adjusted) over a 25-year period.20 For high-transaction denominations like the $5 and $10, which previously wore out in months, the initial investment was paid back in just four years.20

4. Surprising Eco-Friendliness

The most common objection to polymer—"but it's plastic"—is also the most misunderstood. Worn-out paper banknotes are notoriously difficult to recycle due to the inks, security threads, and cotton fibers, and are often shredded and landfilled or burned.44

Polymer banknotes, at the end of their long operational lives, are 100% recyclable.

Furthermore, comprehensive Life Cycle Assessments (LCAs) conducted by the Bank of Canada and the Bank of England both concluded that polymer banknotes have a smaller environmental footprint than paper.

Table 1: Paper vs. Polymer: A Technological Showdown

| Feature | Cotton-Paper Substrate | Polymer (BOPP) Substrate |

| Lifespan |

6-18 months [20, 21] |

8-16+ years (approx. 4x longer) |

| Durability |

Porous; absorbs water, dirt. Tears easily |

Non-porous; waterproof, tear-resistant, high tensile strength [36, 37] |

| Hygiene |

Porous; absorbs oils. Harbors bacteria/viruses for days, even weeks [23, 25] |

Non-porous; repels dirt. Bacteria die off faster, can be wiped clean [41, 42] |

| Core Security |

2D/Embedded (e.g., watermark). Vulnerable to high-res scanning [2, 26] |

3D/Substrate (e.g., window). Cannot be replicated by 2D printing |

| End-of-Life |

Difficult to recycle; often landfilled or burnt |

100% recycled into pellets for new plastic goods (e.g., compost bins) |

| Long-Term Cost |

Low print cost, high replacement cost |

High print cost, low replacement cost. (Net $1B savings for Australia) |

The "Mini-Fortress" - A Deep Dive into Polymer Security Features

Polymer is not merely a substrate; it is a security platform. Its true genius lies in its ability to host a suite of advanced security features that are physically impossible to create on paper. These features are layered, creating defenses that work on three levels: Level 1 (for the public), Level 2 (for cash-handlers with tools), and Level 3 (covert features for central banks).

Feature 1: The Transparent Window

This is the most obvious, elegant, and effective Level 1 feature.

The manufacturing process starts with a 100% transparent BOPP film.

This single feature instantly defeats all casual counterfeiters.

Feature 2: Optically Variable Devices (OVDs) - The Art of Nanotechnology

The transparent window also serves as a high-tech "frame" for even more complex features. Optically Variable Devices (OVDs) are complex images that change their appearance (such as their color or the image itself) when the note is tilted.

A prime example is the UK's £20 note. Its large window features a complex blue and gold metallic foil depicting the Margate lighthouse.

However, "hologram" is a generic term that hides a crucial, expert-level distinction. Most "holograms" seen on consumer products are a publicly known, pixel-based technology.

High-security OVDs, such as the KINEGRAM® (used on the Austrian 500 shilling)

Feature 3: Metameric Inks (The Chameleon Effect)

This is a brilliant Level 2 security feature based on the physics of light. Metameric security involves not one, but a pair of specialized inks.

These two inks are spectrally matched so that, under one light source (like the normal white light in a room), they appear to be the exact same color.

A counterfeiter's inkjet printer, mixing CMYK inks, can only create one color. It cannot replicate the hidden metameric property of two different inks masquerading as one. A bank teller or cashier can use a simple filter to check a suspicious note. If a hidden numeral or pattern does not appear, the note is instantly flagged as a fake.

Feature 4: Intaglio (Raised) Printing - A Sharper Feel

Intaglio is a classic, high-security printing method where thick, heavy ink is applied to the plate with immense pressure, forcing it onto the substrate to create a distinctive, tactile "raised" print that can be felt with a finger.

On porous cotton-paper, the intaglio ink is pressed into the fibers.

On the smooth, non-porous polymer substrate

Feature 5: Microprinting and Covert Features

Beyond these flagship features, the polymer substrate is layered with other defenses. This includes microprint, which appears to be a simple line to the naked eye but is revealed under magnification to be tiny, perfectly legible text (e.g., "£20" or "Bank of England").

The Collector's Angle - The New Frontier of Numismatics

This technological shift from paper to polymer is as significant for numismatists as the historical shift from coin to paper. It fundamentally changes the game for collectors, introducing new opportunities, new risks, and a new class of high-value "rookie" notes.

Pro: The "Uncirculated" (UNC) Advantage

The extreme durability and cleanliness of polymer have a direct and positive impact on banknote grading.

Polymer, by contrast, resists this everyday wear. Its non-porous surface repels the dirt and oils that stain paper, and its flexible-but-stiff nature resists the soft folds and "counting crinkles" that plague paper. A polymer note can circulate for months, or even years, and still retain its "original natural sheen".

Con: The Achilles' Heel - The Permanent Crease

While polymer is incredibly durable, it has one critical, catastrophic weakness: the hard crease. This is the most important piece of advice for any collector or user. Paper folds; polymer creases.

This is a problem of material science. Paper is a mat of fibers. A "soft fold," like one from being in a wallet, is just a temporary bend in those fibers. It can often be flattened or "pressed" with minimal long-term damage. Polymer (BOPP), on the other hand, is a stretched film. A hard crease—the kind formed by folding it sharply—is not a "fold"; it is a point of material failure. The stretched polymer is bent beyond its elastic limit, causing a permanent, sharp white line where the material has been stressed.

This damage is irreversible. For grading purposes, it is a catastrophic defect, far worse than a soft paper fold, and will permanently destroy a note's Uncirculated status. Central banks explicitly warn users to never fold, crumple, or crease their polymer notes.

Collectors must also be aware of other handling cons: the notes are "slippery" when new and can be "sticky" when wet.

Pro: Collecting the "Firsts" - The New Holy Grails

For serious numismatists, the true excitement is in collecting the "first generation" of this new technology. These notes are the equivalent of "incunabula" (the first books printed in the 15th century) for modern currency. They mark the very beginning of a new age.

1. The Originator: 1988 Australian $10 Bicentennial Note

This is the must-have for any serious polymer collection.9 It is the genesis of the entire technology. But not all 1988 notes are created equal. The expert-level detail lies in the serial number prefix.10

-

The first production run—the true "first issue" with the early, flawed hologram—had serial number prefixes beginning with "AB 10" and running to "AB 33".

10 -

The second, retooled production run (with the improved hologram) was released in October 1988 and had different prefix ranges.10

The value difference is immense. A standard 1988 $10 note in a commemorative folder might sell for $25-$60.78 An Uncirculated note from that first, rare "AB 10" prefix batch, however, is a prized collector's item, with recorded sales reaching $395.80

2. The "Frontier" Series (Canada, 2011-2013)

This series is highly sought-after for its stunning design, its "technical innovation" theme, and its unique story.81 The $100 note (medical innovation) and $50 note (Arctic research) were the first to be released, but the $5 and $10 notes in 2013 truly captured the world's imagination.

The $5 note, featuring the Canadarm2 robotic arm, had the most spectacular unveiling in numismatic history. It was introduced to the world live from the International Space Station by Canadian astronaut and Expedition 35 Commander, Chris Hadfield.81 This collision of numismatics and space exploration makes the "Frontier" series, particularly in a full uncirculated set 83, a modern classic.

Table 2: The Polymer "First Issues" Checklist

| Country | Note | Year | Numismatic Significance |

| Australia | Bicentennial $10 | 1988 |

The world's first polymer banknote. "AB 10" prefix is the holy grail.[8, 80] |

| Singapore | Commemorative $50 | 1990 |

Singapore's first polymer note; an early and influential adopter.[84] |

| Romania | 2000 Lei | 1999 |

First polymer banknote in Europe. Famously commemorated the 1999 solar eclipse.[11, 85] |

| New Zealand | $5 - $100 Series | 1999 |

First country after Australia to fully convert all denominations to polymer. |

| Canada | Frontier Series | 2011-2013 |

Canada's first full polymer series. The $5 note was unveiled from the International Space Station. |

| United Kingdom | £5 Churchill | 2016 |

The Bank of England's historic first polymer note, marking a major shift for a global currency.[11, 16] |

Conclusion: The Future of Money is Physical and Digital

Polymer is not a gimmick. It is not a temporary trend. It is, unequivocally, the new global standard for physical currency—a platform that has proven to be more secure, more durable, cleaner, and more cost-effective than the paper it replaces.

But polymer is not the end of the story. It is the platform for the next evolution of physical money.

The Next Frontier: "Smart Banknotes"

The true "futuristic" potential of polymer lies in what can be added to it. The durable, non-fibrous substrate is the perfect vehicle for embedding advanced electronics, creating a "smart banknote" or "hybrid banknote".

This would create a physical currency with digital capabilities:

-

Ultimate Authentication: A user could tap their smartphone to a banknote. The NFC chip would communicate with the phone, which could ping a central bank server to verify that serial number in real-time.

90 -

The Digital "Bridge": A smart banknote could be "activated" or "deactivated" remotely, or have its value electronically transferred to or from a digital account.

86 87

Co-existence in the Age of CBDCs

Many assume the rise of digital payments and Central Bank Digital Currencies (CBDCs) means that physical cash is dead.

Central banks and the public are not abandoning physical cash.

The future is not one or the other; it is co-existence.

Collecting polymer notes, therefore, is not just collecting "plastic money." It is collecting the cutting edge of numismatic history. It is the first chapter in the next thousand years of physical currency.

Explore Popular Articles

Gold $5,600 & The 2026 Refining Crisis: The Great Repricing

The Great Repricing: A Century of Precious Metals Volatility and the 2026 Systemic Refining Seizure...

Gold Hits $5,000: The 2026 Strategic Metals Market Report

STRATEGIC MARKET INTELLIGENCE: THE MONETARY BIFURCATION AND THE TANGIBLE ASSET PIVOT MONDAY MARKET...

The $17 Billion Signal: Iraq’s "Development Road" & The Dinar’s Path to Global Trade

Republic of Iraq: Strategic Economic Reintegration Currency Normalization Outlook (Q1 2026) To: Ins...